Hits: 635 img

In the field of sealing materials, hydroxy silicone oil is hailed as the "bonding master" due to its exceptional adhesive properties. This special organic silicone material is providing crucial technical support for various sealing products.

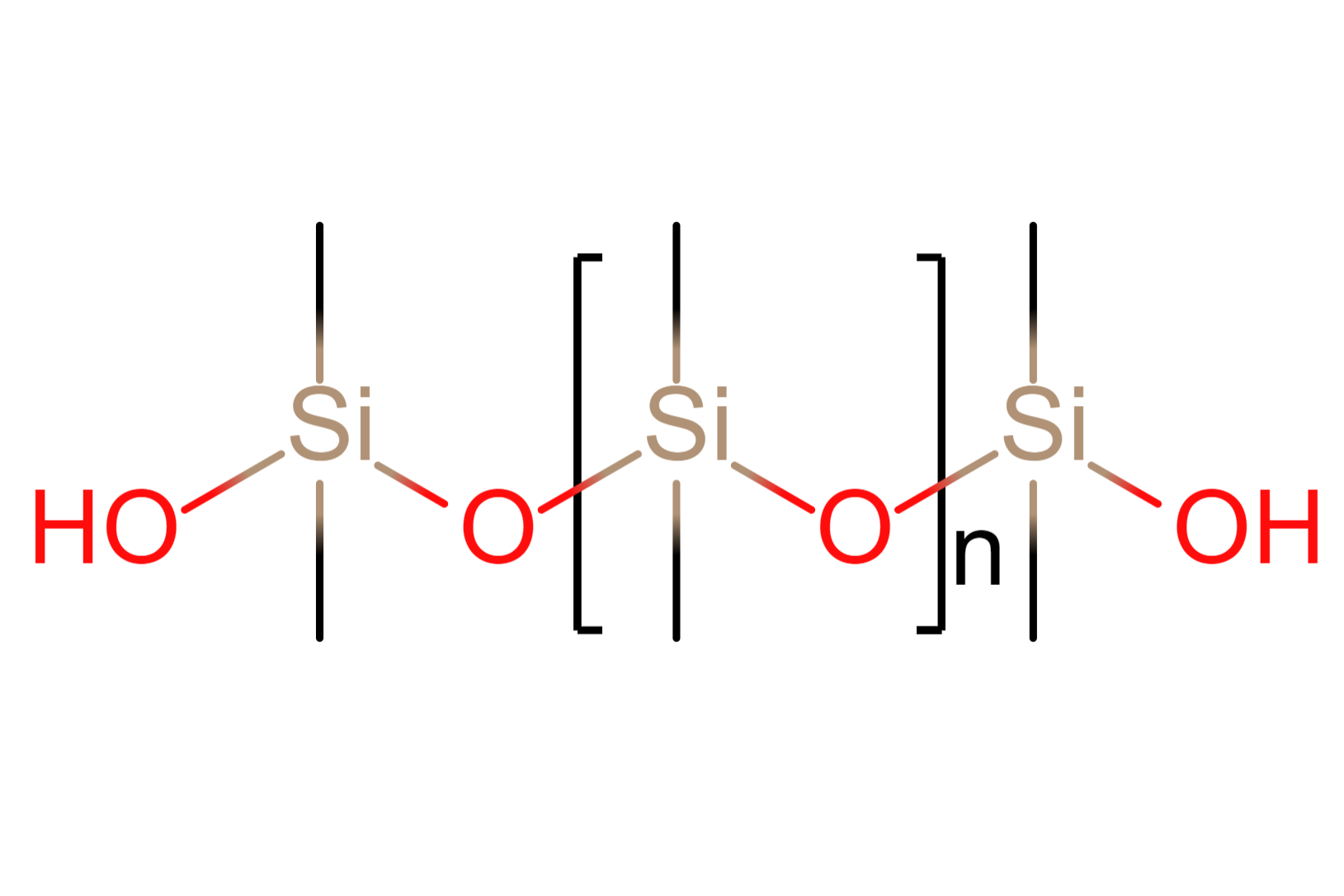

Hydroxy silicone oil production uses special hydrolysis processes, where hydroxyl groups are introduced at the ends of siloxane chains by controlling hydrolysis conditions. During production, hydroxyl content and molecular weight control are key, as they directly affect the product's adhesive properties. High-hydroxy-content products have excellent reactivity, making them ideal raw materials for high-performance sealing materials.

In the field of room temperature vulcanizing (RTV) silicone rubber, hydroxy silicone oil demonstrates unique advantages. It is used as a base polymer, forming elastomers with excellent sealing properties through reactions with crosslinking agents. Statistics show that sealants prepared with hydroxy silicone oil have bonding strengths over 30% higher than ordinary products.

Hydroxy silicone oil also has important applications in electronic packaging. It is used to develop high-performance electronic packaging materials, effectively protecting electronic components from environmental factors. Especially in LED packaging, hydroxy silicone oil-based materials have excellent light transmission and weather resistance, significantly extending LED lifespan.

As the electronics and construction industries develop, the demand for hydroxy silicone oil continues to grow. In the future, through molecular structure optimization and functional modification, even better-performing sealing materials may be developed, providing stronger technical support for various industries.